Tips for Using Engineering Plastic

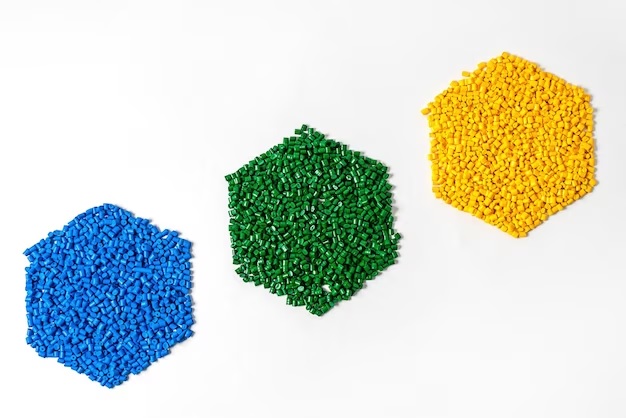

Engineering plastic is a widely-used material in various industries, such as automotive, electronics, and manufacturing. The popularity of this plastic material in industries is due to its advantages, such as its resistance to high temperatures, pressure, and chemicals, as well as its high strength. However, to maximize the performance and durability of engineering plastic, it is necessary to consider some tips.

Here are some tips for using engineering plastic that can help you optimize its use.

- Choose the Right Material

Each type of engineering plastic has different characteristics, such as strength, stiffness, and resistance to high temperatures or specific chemicals. Before selecting the material to be used, it is important to consider these factors so that you can choose the right material for the desired application.

- Pay attention to size and dimensions.

The use of engineering plastic also requires consideration of the appropriate size and dimensions for the application. It is important to choose the correct size and dimensions to minimize the risk of structural failure or leakage in a system.

- Consider environmental conditions

Environmental conditions can affect the performance and durability of engineering plastic. For example, high temperatures or certain chemicals can affect the resistance and strength of the material. Therefore, it is necessary to ensure that environmental factors are taken into account when selecting and using the material.

- Avoid direct sunlight exposure.

It is important to avoid direct exposure to sunlight because it can affect the performance and durability of engineering plastic. Continuous exposure to sunlight can make the material brittle and easily breakable. Therefore, it is necessary to ensure that engineering plastic is protected from direct sunlight exposure.

- Avoid using incompatible chemicals.

Certain chemicals can damage and dissolve engineering plastic. Therefore, it is important to select chemicals that are compatible with the type of engineering plastic being used. If unsure, it is best to consult with the manufacturer or technical experts to ensure the appropriate use of chemicals.

These are some tips for using engineering plastic. For those who need it, ADP can be trusted as a leading polymer provider in Indonesia with over 30 years of experience. In addition to commodity plastic and engineering plastic, ADP also offers other products such as polycarbonate (PC), ABS, Nylon, polyacetal (POM), PMMA, and polystyrene. With our products, ADP is ready to help and meet your industrial needs with a one-stop raw material solution. For more information about us, please visit our official website at https://adpi.co/.