Get to know the uses of ABS Injection Molding

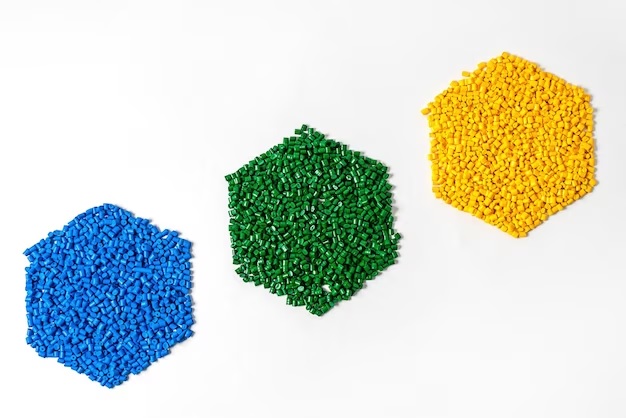

What is ABS plastic ?

ABS is short from Acrylonitrile Butadiene Styrene, thermoplastic amorphous which is not translucent light and also could stand to crash. This is wrong, one popular choice for injection molding, as well as polymer made from three monomers, according to his name. Because made of from ingredient amorphous , so ingredient this no have ingredient real melt .

Profit Using ABS injection module

ABS, or Acrylonitrile-butadiene-styrene , is a type of plastic used for print injection . With using the ABS injection module you have a number of very useful advantages for your industry . The profit will be obtained among them are :

1. Efficiency energy

Machine used _ for printing ABS plastic has very good performance for processing thermoplastic this . Dynamics and power you have by machine that ensure performance sustainable production _ and repeated . Besides that’s the machine this also has advantages economical energy yes could help You for reduce Request energy as well as time cycle whole .

2. Various Application

ABS plastic molding too could help flexible application. This process is customized for work with ABS resin with various sizes with great ability integration ok . With flexibility this so very much helps various industries in production .

3. Accurate Reproducibility

ABS Injection molding process produces complex parts for complex application. This often stamped in other injection molding processes . Ability to use complementary and print regulated injection _ ensure making possible form reproduced and part quality mold. Besides that, materials can maintain characteristics and guard performance although they experience drastic temperatures.

4. Strength and durable

One of the main advantages of ABS Injection Molding is the strength and durability of the resulting product. ABS material has excellent strength and ductility, so products made using this technique are durable and can last a long time even under harsh conditions.

5. Flexible nature

ABS Injection Molding has flexible and elastic properties that allow the product to withstand strong impacts and pressure. This makes ABS Injection Molding very suitable for products that require high physical resistance such as children’s toys or automotive equipment.

6. Ease of printing and design

The ABS Injection Molding process allows products to be made in various shapes and sizes according to design requirements. ABS materials are very easy to machine and model making it possible to manufacture more complex products with high accuracy and precision.

7. Easy to color and logo print

ABS material is also very easy to color and print logos, thus making products more attractive and easily recognized by consumers. In addition, the ABS Injection Molding process also makes it possible to print products with predetermined logos and brands, so that the products become more personal and exclusive.

8. Environmentally friendly

ABS material is an environmentally friendly material and can be easily recycled. This is very important in supporting environmental programs aimed at reducing waste and improving environmental quality.

A number of necessary thing noticed in the Molding Process Injection ABS plastic

Wall design on component plastic needs to have the same thickness with a range of 25% in between thickness Wall from part the. With thickness, a uniform wall is possible for massive prevention .

Before processing molding injection ABS plastic, you need to notice a number of p . Following a number of guide that will ensure successful printing and desired result :

Consider Design Component ABS plastic

Next , the thickness Wall could determine a big, small radius. So from it, you need to notice the ratio fingers have thickness no not enough from 0,3 . If the radius is , then make the pressure smaller. However, you also need to be careful because a larger radius can result in depreciation . So it is necessary also for consider possible depreciation during the molding process Injection ABS plastic .

Temperature Print

Need to consider temperature print to ensure good production results. If the temperature is too low, it could make particle plastic not melt well, so could make results print bad. However, with too high temperatures also not well, because it can cause warping, deformation, or even damage mol.

Speed Injection

Speed injection also is a necessary thing noticed because it could ensure good results. If speed injection low so could cause plastic not distributed with evenly inside mold, so make results print Becomes bad. Height speed injection also could cause problems like warping or deformation.

Those are the uses of ABS Injection Molding, for those of you who need it, you can trust ADP. ADP is a leading polymer provider in Indonesia with more than 30 years of experience. In addition, it is also ready to help every industry to serve leading manufacturers in various industries by offering one-stop raw material solutions to meet all your needs. For example various kinds of plastic commodities such as engineering plastics, super engineering plastics, coatings and additives. For more complete information, please visit our official website at https://adpi.co/

Read Also : Utilization of POM Injection Molding