Polyethylene Terephthalate Glycol and Explanation

PETG (Polyethylene Terephthalate Glycol) is a type of plastic that is often used in the injection molding process. PETG has unique characteristics, such as strength, hardness, clarity, and resistance to scratches and chemicals. This article will discuss more about PETG injection molding in Indonesian.

PETG Injection Molding Process

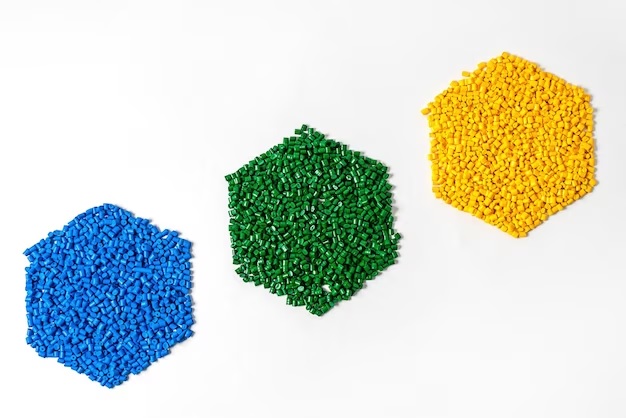

The PETG injection molding process begins by melting the PETG plastic into a homogeneous liquid. Then, this liquid will be injected into the mold under high pressure. After that, the mold will be cooled until the PETG plastic hardens and takes the shape according to the mold design.

Advantages of PETG Injection Molding

One of the advantages of PETG injection molding is high strength and hardness. PETG is also highly transparent, so it is often used for products that require clarity, such as beverage bottles, food packaging, and electronic products.

In addition, PETG is also resistant to scratches and chemicals, making it very suitable for use in products that require durability such as smartphone cases, medical devices, and automotive products.

The PETG injection molding process can be used to print products with high strength, hardness, clarity, and resistance to scratches and chemicals. However, higher production costs and difficulties in the recycling process can be drawbacks of this process.

In an industrial context, the PETG injection molding process can help improve production efficiency and produce high quality products. However, it is also necessary to pay attention to the environmental impact of using PETG plastic which is difficult to recycle. Therefore, efforts are needed to find alternative materials that are more environmentally friendly without compromising product quality.

In an effort to overcome the shortage of PETG, several companies have innovated to produce products that are more environmentally friendly. One way is to use PETG recycled materials or PETG bio-based materials.

PETG recycled materials are obtained from the processing of PETG plastic waste taken from products that are no longer used. Meanwhile, PETG bio-based materials are obtained from renewable natural resources, such as sugarcane and corn, thereby reducing dependence on petroleum resources.

In addition, companies can also consider using other technologies, such as the injection molding process with biodegradable materials. Biodegradable materials can be naturally decomposed by microorganisms, so they don’t leave plastic waste that damages the environment.

In this regard, innovation and the development of new technologies can help increase production efficiency, improve product quality, and reduce the environmental impact of plastic use. In the long term, the use of more environmentally friendly materials will become imperative, so companies must be prepared to adapt to these changes.

The PETG injection molding process can produce high-quality products, but it is necessary to consider the environmental impact of using plastics. Innovation and development of new technologies can help companies produce products that are more environmentally friendly. In the long term, the use of more environmentally friendly materials will become imperative, so companies must be prepared to adapt to these changes.