The Difference between Commodity Plastic and Engineering Plastic

Plastic is a synthetic material made of polymers, which are large molecules formed from many small monomer units that are bound together. Plastic is often used in industries because it is lightweight, durable, and can be shaped into various forms and sizes.

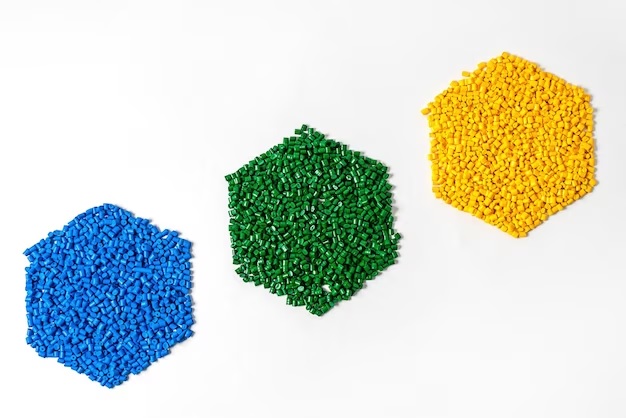

In the plastic industry, there are two commonly used types: commodity plastic and engineering plastic. Although both are widely used in the industry, these two types of plastics have very different characteristics.

Commodity Plastic Commodity plastic is one of the most commonly used types of plastic in everyday life. This type of plastic is used to make plastic products such as water bottles, shopping bags, toys, and many more. It has a relatively cheap price and can be easily produced in mass quantities.

Commodity plastic has the characteristic of being able to melt at a relatively low temperature. In addition, it is easy to shape and process in various sizes. Unfortunately, this type of plastic often has characteristics that are not suitable for use in applications that require stronger physical properties, wear resistance, and higher temperatures.

One example of commodity plastic is PVC.

Engineering Plastic Engineering plastic is a type of plastic that has stronger physical properties, wear resistance, and higher temperature resistance than commodity plastic. This plastic is used for applications that require higher mechanical strength, such as in the automotive, aerospace, and electronics industries.

The properties of this type of plastic can vary depending on the polymer used and the production method. However, generally, engineering plastic has high tensile strength, wear resistance, and can withstand higher temperatures compared to commodity plastic.

When choosing plastic for a product, it is important to consider the product’s usage and requirements and choose the appropriate material. Commodity plastic is suitable for products that do not require special mechanical or thermal properties, while engineering plastic is more suitable for applications that require special properties such as high mechanical strength or resistance to chemicals.

That is the difference between Commodity Plastic and Engineering Plastic. So, for those who need it, you can trust ADP. ADP is a leading polymer provider in Indonesia with more than 30 years of experience. In addition, ADP is also ready to help every industry to serve leading manufacturers in various industries by offering one-stop raw material solutions to meet all your needs. In addition to Commodity Plastic and Engineering Plastic, ADP also offers other products such as polycarbonate (PC), ABS, Polyamide / Nylon, Polyacetal / POM, PMMA, and Polystyrene. With the products we offer, ADP is ready to help and meet your industrial needs. For more information about us, please visit our official website at https://adpi.co/.